Previous Article

Previous Article

Navigating the Composite Decking Market: How to Choose the Best Brand for Your Project

Many people use the internet to research and browse for decking types that are suitable for their desirable home, in an ever-expanding market that grows more diverse yearly. The wide variety of decking profiles, structures and designs can leave you confused and overwhelmed for choice by what is available online or in-store.

When it comes to decking construction, you need to decide what type of composites you’ll use; finding the perfect one will be crucial to your project. We are here to explain why there are different types of composite decking and which type is best for your home/property.

There are many suppliers of composite decking on the market; each one of them is different from the other. When choosing the right composite decking for your project, they can be narrowed down by classifying them into different types.

If you are anything like me, you want something to showcase!

As there is a lot of information to absorb and digest on this page, feel free to jump to the information you are looking for or review our ‘quick glance’ table on all types of composites compared.

Review our table on all types of performance point that matters most to you, allowing you to quickly glance to see which decking is best for your project.

Here is a summary of the different composite decking types to help you find the perfect one for your project.

| Feature | Capped | Uncapped | Solid Composite | Hollow Composite |

|---|---|---|---|---|

|

|

|

|

|

|

| Price | Higher | Lower (Budget-friendly) | Highest | Affordable |

| Maintenance | Ultra-Low (Wipe clean) | Low (Regular cleaning) | Low (Regular cleaning) | Low (Regular cleaning) |

| Stain & Mould Resistance | Excellent | Vulnerable | Vulnerable | Vulnerable |

| Fade Resistance (UV) | Highest (Minimal fading) | Good (Fades initially) | Varies (Good to High) | Varies (Good to High) |

| Durability & Strength | High | Good | Highest (Impact resistant) | Good (Strength varies by core shape) |

| Authentic Appearance | Varies (Can look plastic) | Good | Highest (Impact resistant) | Good (Strength varies by core shape) |

| Best For | High footfall, South-facing gardens, Long-term investment | Budget-conscious buyers, Average family homes | Commercial settings, High-impact areas, Maximum longevity | DIY installation, Running cables, Standard residential projects |

Capped composite decking often referred to as “second generation or shield” (Shield*) boards are produced with a protective co-extrusion layer, which acts as a shield against Mother Nature’s elements. They boast increased moisture resistance, absorbing less than 1% of moisture in most cases; this resistance prevents the risk of mould and mildew growth. Due to its low absorption of moisture, food and drink spillages from social gatherings with family and friends can be simply wiped away.

If that wasn’t enough benefits for you to enjoy, they also see increased colour consistency and stability, producing a delta E of below 2 after 100 hours of consistent UV ray exposure; this means in most cases that there will be no visible colour change.

This material will only lose minute amounts of colour, depending on the quality of board; the reduction in colour can be as little as 5-10% throughout its lifespan, meaning it is more suitable for a home that is south-facing and will be exposed to more sunlight.

Tech term: Delta E measure the change in colour to the highest standards compared to grey scaling, put simply, if Delta E was a measurement it would be the change in the mm. It’s the most accurate testing on colour change done in EN standard.

Capped boards were introduced into the US Market due to the promise of a first-generation WPC decking being completely maintenance free, with the bonus of being resistant to UV fading, staining, mould and mildew ultimately being short lived.

Therefore, the industry was forced to adapt and embarked on sustained research and development, to produce an ultra-low maintenance product that truly resisted fading, staining, mould and mildew; hence the birth of second-generation wood-plastic composite decking with a 0.5mm capped or shielded surface texture.

The genesis of this product ensures that you have a new composite decking solution that offers low or no maintenance, can resist UV fading, staining and mould and mildew growth.

Customers reacted very positively to the introduction of second-generation composite decking and today you will find that in some global markets only second-generation composite decking are on offer, with first generation composite decking being completely discontinued.

The only negative feedback on the new second-generation, shielded technology was that the boards appeared to look plastic and cheap in their appearance, not really providing the authentic wood-like texture and appearance research set out to achieve. This drawback in appearance put customers off from purchasing. The market was demanding an authentic wood look and colour retention, without the annoying maintenance associated with wood. So far, second-generation composite decking boards had failed to achieve a natural wood look; indeed, even today some manufacturers are still failing to achieve it, without producing cheap-looking plastic boards.

Leading manufacturers and suppliers (link home page) listened and continues to perfect their designs and manufacturing processes to produce a composite decking board indistinguishable from real wood.

Capped composites are relatively stronger and more durable than their older counterparts. They are easier to maintain and offer excellent fade and stain resistance when compared to uncapped or wooden decking.

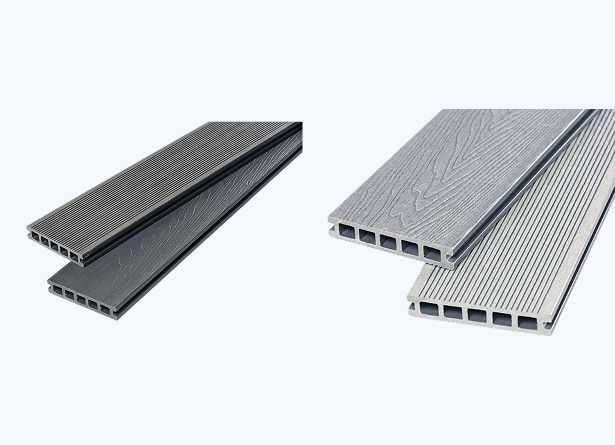

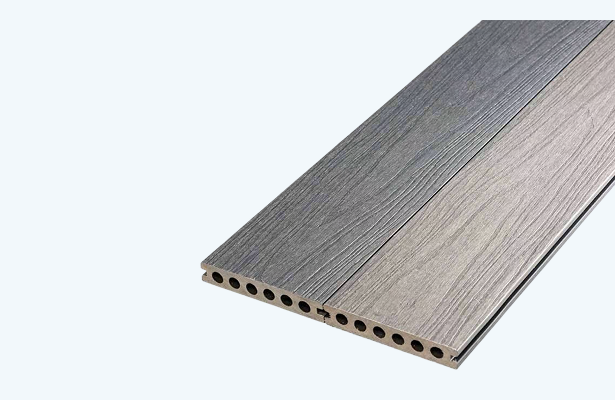

Capped composites often have a reversible woodgrain appearance and an applied PE layer that wraps around the board. Some capped composite decking designs now offer a dual-colour design; this means that one surface is a different colour from the other. The advantage and benefit of this, is it allows you to reverse the entire composite decking board to provide a new colour years later or even create contrast designs using one singular board.

Capped boards tend to have a circular hollow structure which is stronger than the square hollow structure. In essence, the decking board has more material in the design making it more dense and structurally sound.

Capped boards are also more suitable for properties that will have a lot more footfall, such as commercial settings like restaurants or apartment complexes.

Due to their increased added benefits, the capped boards do come at a higher price compared to uncapped versions. The realism is will you benefit from these improved benefits and advantages. If you want to sit back, relax and enjoy the benefits of a fruitful investment, then yes, they are worth purchasing.

If you’re like me and have 5 grandkids, you’ll know they are prone to constantly spilling and dropping food, further highlighting why this is worthwhile investment. It all depends upon your personal preference and understanding whether these benefits really matter to You.

So now we understand capped boards, their strengths and performance, why would anyone consider purchasing for uncapped? The reason uncapped boards are still a popular option in the UK is, we don’t see a large amount of UV ray exposure compared to that of the USA & Australia, so colour stability and fading are not as intense; however, this is a minor reason, the better one is cost.

But first let’s look at what they are and then move on to performance and cost.

Uncapped decking boards are often referred to as first generation composite decking in the industry. First-generation decking boards are produced with a wood fibre surface layer rather than a PE layer; this provides in consumer eye’s more authenticity in appearance and feel. While uncapped composite decking boards are sturdy, they are more vulnerable to damage, including moulds, mildew, fading, and staining. These types of older composites need to be maintained regularly to prevent damage.

As mentioned, uncapped decking boards will fade more than capped decking boards; wood fibre surface layers are not as resistant to UV rays and are not as hard-wearing when compared with second-generation boards.

A key point to remember is that uncapped composite decking board surfaces are made from real wood fibres, helping to achieve a natural wood grain appearance. However, this type of first-generation or traditional uncapped composite decking board goes through a natural weathering process.

For the first 3-6 months of the decking boards life, they will fade from exposure to the Sun’s UV rays. However, good quality boards will colour stabilise after this initial weathering period due to a manufacturing process that makes use of Grade ‘A’ quality recycled plastics.

These plastics are of the highest quality and are mainly imported from the USA and Europe, to produce a composite decking board with improved fade resistance properties built in. Although the colour fades during the first 3 months, it is gradual and very minor, which most customers even rarely notice.

Contrary to the advice and information given by many decking manufacturers that the boards do not fade, all decking products, natural or engineered will experience weathering.

Uncapped boards are still an excellent option for residential homes with an average amount of footfall (a family of 4-5 people). They come with 10 to 15-year warranties depending on supplier; this means if you have any structural defects or issues with the product, you are entitled to a replacement material. Given that first-generation decking boards aren’t as long-lasting as second-generation boards, they are priced more competitively meaning they are more suitable for someone on a budget.

Cost is a large contributor that makes these boards popular, but why? After listening to customer feedback for almost a decade, we have devised that customers are happy to comply with the colour changes and regular cleaning. This reasoning is understood to be that they use to wood; even though uncapped boards don’t boast the level of upgrade versus vying for the option of capped decking, it is a major improvement when compared to wood.

They don’t need to ever be sanded, sealed or stained, they keep their base colour; it does lighten, but our feedback is it remains the base colour – brown remains brown, and grey remains grey. They last longer than traditional wood and after 5 years, this investment pays for itself.

So, if you’re happy to accept some colour changes and some regular cleaning, then uncapped is the choice for you; they are at least 20% cheaper than capped boards.

There are two designs with uncapped decking boards, Grooved and Woodgrain.

| Grooved | Woodgrain Boards |

|---|---|

|

|

| Grooved boards feel like the ‘timeless classic’, they are the first addition in a line of uncapped boards. They come with a reversible grooved finish that captures the traditional grooved wood decking we see here in the UK. They almost always have a sanded finish and are robust, standing the tests of time, they are a perfect entry-level pattern for buyers | Woodgrain boards are (in most cases) a deep-embossed, wood effect pattern that is pressed into the board, but why should you be careful? Many years ago, the wood effect was a print on pattern that would fade away in time; the steps taken to eliminate this was an embossed pattern that was manufactured into the board. They are produced to capture the natural wood grain to create a more authentic appearance, more representative of true woodgrain patterns |

As mentioned, you should check if the woodgrain pattern is manufactured and embossed into the board; an easy way check this is if the surface is rough from the waves of the pattern or smooth. If it’s rough, then you can be assured it’s embossed; if not it’s almost certainly a printed pattern of wood grain.

As an aside from this, the treatment after production matters. Without giving away some of our secret in design and development, we shall take you through the types of treatment and how they affect the boards performance.

Sanded surface treatment is when the top surface is sanded on the board, creating light and dark points across the external surface, where the treatment process has reached. So, how does this relate to performance? – They see a better, more light-weight stability in colour, compared to a brushed finish below, they appear more weathered and rough – which some customers enjoy and some don’t.

The surface is brushed instead of sanded, leaving a richer, sharper colour. It is not as glossy and plastic as an untreated board but produces better visuals and texture, with no single contour that is consistent throughout.

After rigorous lengths of testing some suppliers have uniquely produced a board that is rich in colour, shape and still gives a rough texture for authenticity. The benefits don’t stop here though, with visuals that perform better than both sanded and brushed treatment. From internal testing and combined with the qualities of previous iterations, they see an improved stability and long-lasting colour; they may look similar, but these new surface treatment boards perform better.

Supplier Note: An example of this can be seen in wood grain grey boards here.

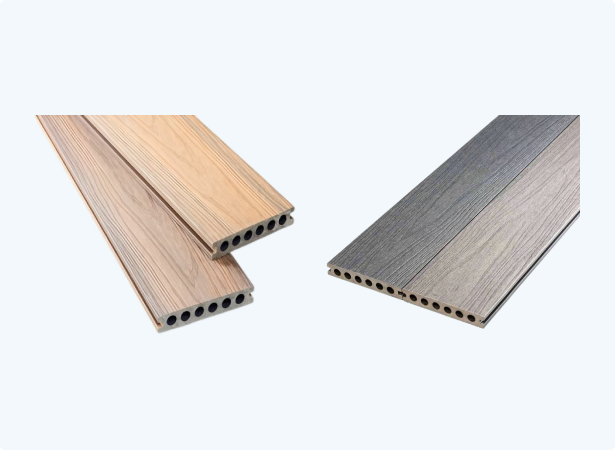

Composite decking has continually evolved during its 30+ year life span. In the early 2000’s a printed woodgrain finish was introduced, further evolving from 2010 onwards; becoming a deep-embossed woodgrain finish that is surface treated, brushed and sanded to provide a cleaner and more authentic wood look.

The latest techniques and methods being used to perfect a natural woodgrain appearance are with the use of computer-aided technology (CAD). Borrowed from the aerospace and car industries, it introduces a mix of colours at randomly programmed intervals to provide lighter and darker colours, offering a further authentic wood appearance indistinguishable from real wood.

These next generation wood-plastic composite decking boards come with two design profiles: A square hollow structure specifically designed and developed for our residential customers and a solid composite decking board.

Extensive market research and product development has produced a composite board that needs to be seen to be believed; not actually composed of regular timber and with none of the maintenance drawbacks associated with an exotic wooden or timber deck.

Key Note: New Mixed colour seen in leading suppliers boards takes the beauty and authentic wood appearance to a whole new level.

Hollow composite decking, unlike solid composites, is a lightweight decking made with fewer materials. Because of this, they are cheaper and easier to work with. As the name implies, they have hollowed segments within the board, perfectly suited for an ease and speed of installation, due to the boards lightweight design; during installation cables and wires can be ran through the hollow core.

Hollow decking boards are much more common when compared with solid composite decking boards. Solid composite decking boards are produced with more material within the core meaning the cost of materials quickly increases, and the manufacturing process overall takes longer when compared with hollow.

Common Question: You may be wondering: ‘Will hollow decking boards be strong enough for my project?’

The overall structural integrity of your decking boards will mainly come from the decking subframe and the span of the joists beneath the decking boards. However, if you are looking for a strong decking board that is still affordable, there are different designs to consider when looking at hollow decking boards. For example, you have 4 square hollow designs and 5 square hollow designs. A 5 square hollow will be more durable as it’s like a building having an additional pillar.

As mentioned previously, another design for hollow decking boards is a circular hollow design. This is the strongest design for a hollow decking board, and you will often see capped decking boards with this core. Despite all these advantages, there are cons to using hollow composites. Unlike solids, they often look like manufactured materials and are more prone to damage from impacts. For more information on hollow boards versus solid see our article. (SIGNPOST HERE)

Another composite decking design is a completely solid structure. This structure provides numerous benefits including enhanced durability, longer life span and an excellent impact resistance. With an extended life span, solid composite decking boards can last up to 30 years with no structural issues or defects. The added mass and amount of material used for production creates a landscaping material that can withstand a large amount of weight and pressure, and is an excellent option for busy commercial settings such as hotels or popular restaurants.

While solid composites are excellent choices, they do have some disadvantages. Since they are heavier, solid composite decking boards are harder to work with, usually during installation; they are also more prone to increased expansion – leaving the gaps is important when installing. Solid composite boards are considerably more expensive than traditional wood and hollow composite decking boards, so you should expect to spend more when opting for this choice

As the composite decking market expands, understanding the different available options is crucial. Uncapped hollow boards are the best-selling composite decking in the U.K. They are affordable and offer low maintenance with strong colour stability when compared to wood; however, they are not as moisture-resistant and will fade over time when compared with capped boards.

Capped composite decking offers increased durability, along with increased stain and fade resistance. They are ultra-low maintenance, only requiring simple cleaning regularly. They offer a longer life span and visual stability even after many years of use. These added benefits are beneficial to customer’s that are looking for a long-term solution, and a return on investment that comes with these boards after a decade of use.

The key questions to ask upon purchasing is ‘How long will you be in your property for?’ and ‘What level of maintenance and colour change can you accept?’ – If the answer is minimal then capped composite decking is the product for you.

Previous Article

Previous Article

Navigating the Composite Decking Market: How to Choose the Best Brand for Your Project

How Stain-Resistant is Composite Decking? An Engineer's Guide