Previous Article

Previous Article

A UK Guide to Decking Subframes & Joists

When choosing composite decking, one of the most debated topics is the core structure: should you choose a hollow or a solid board?

Some companies that only sell solid boards publish negative information about hollow decking. While it’s true that hollow boards use less material and are generally cheaper, this is by design. Modern hollow decking is expertly engineered for a perfect balance of strength, stability, and value for residential use.

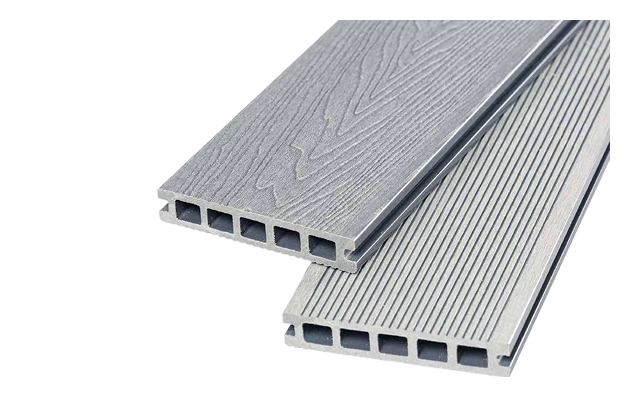

These boards feature square-shaped channels running through the core. They were designed specifically to reduce the amount of material needed, which in turn reduces the cost for the homeowner. They are the most common and affordable type of composite decking in the UK and are primarily designed for standard residential projects.

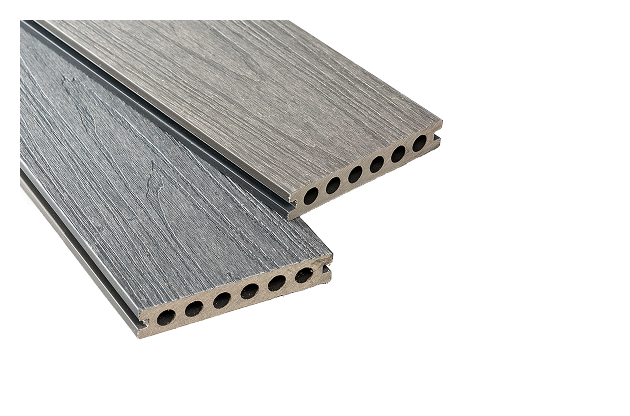

Often called a “honeycomb” design, these boards feature circular channels inside. A circle is an inherently stronger shape than a square, so this design provides a huge increase in strength and rigidity while still being lighter and more cost-effective than a solid board. It represents the perfect blend of performance and value.

These boards are solid composite material all the way through, with no hollow channels. They are denser, heavier, and offer the highest possible strength, making them suitable for heavy-duty commercial applications.

| Board Core Type | Average Flexural Strength (MPA) | Best For... |

|---|---|---|

| Square Hollow | 23 - 26 MPa | Standard residential decks |

| Circular Hollow | 34 - 36 MPa | High-traffic residential & light commercial |

| Solid Core | 46+ MPa | Heavy commercial use; where cost is no object |

As the data shows, solid core boards are the strongest overall, equivalent to holding the weight of more than four cars per square inch.

However, the key takeaway is the performance of the circular hollow core. It offers a massive jump in strength over the standard square hollow and provides a high strength-to-weight ratio that even solid boards can’t match. The circular “honeycomb” structure distributes weight and impact shock evenly, whereas a square core has weak points at its corners. This makes a circular hollow board an incredibly efficient and robust design.

Expert Tip: When inspecting a square hollow board, the most important factor is not the overall depth of the board itself, but the thickness of the walls inside the core. We recommend a minimum wall thickness of 5mm to ensure the board has the necessary structural integrity for its service life

Another critical factor is how a board reacts to the UK’s changing temperatures. This is measured by the “Linear Thermal Expansion Coefficient” a lower number is better.

Our robust, independent testing has concluded that a circular hollow board offers the best rate of expansion.

In layman’s terms: a standard square hollow board will expand more than a solid board, and both will expand more than a circular hollow board. This is because the dense design of a solid board doesn’t adapt to rapid temperature changes as efficiently as a well-engineered hollow design. While all composite decking requires correct expansion gaps during installation, a more stable board reduces the risk of warping over time.

The choice depends entirely on your project’s specific needs and budget.

your number one priority is affordability for a standard residential deck. If installed correctly with 300mm joist centres, a high-quality square hollow board is a brilliant investment that will provide decades of enjoyment.

you are looking for the smartest all-around choice. It offers a significant increase in strength and stability, making it perfect for high-traffic family decks or light commercial projects. It delivers performance very close to a solid board but at a more effective price point.

maximum strength is your only priority and cost is not a factor. For 90% of residential and light commercial projects, a solid profile is not required. It is primarily built for heavy commercial areas with huge footfall.

Previous Article

Previous Article

A UK Guide to Decking Subframes & Joists

A UK Homeowner's Guide to Replacing Wood Decking with Composite (2025)