Common Customer Questions Answered

It is worth noting that not all composite decking boards are created equally. If you’ve been considering and researching the available decking options, you will no doubt come across wood, composite (traditional) and co-extrusion composite decking, often referred to as capped or shielded decking.

Ultra Decking has performed extensive research and development into fine-tuning the manufacturing process of our Signature, Exclusive, Premier and Home Choice range of composite decking boards. Research and development is taken with a view to achieving the most authentic and aesthetically pleasing wood-looking grain appearance that is also extremely strong and durable.

On this page, we review the industry terms Traditional Composite decking and capped or co-extrusion composite decking. We look at the pros and cons of all the different generations of composite decking to help provide you with more knowledge to help you make the best-informed choice of what type of decking is best for you.

Please note there are many different types of composite decking surface textures and designs. For more knowledge, please visit our knowledge section on “what is the best composite decking” which helps to explain in more detail the different types of composite decking currently sold here in the UK and globally.

Traditional Uncapped Composite Boards

Uncapped composite decking is also known in the industry as first-generation composite. Traditional composite decking has a different surface texture compared to the latest capped or shielded co-extrusion composite boards currently in the market. First generation composite decking boards are in the main a cheaper solution.

So, what’s the difference in the surface texture?

Traditional composite decking boards are made from wood fibres and oil-based surface texture. Offering a more realistic natural wood grain appearance especially with the deep embossed Premier range. First generation or traditional composite decking boards come in many different forms of surface texture and different types of profile depths and thickness. For more information on decking board profiles please follow the link.

A key point to remember is that composite decking boards surface is made from real wood fibres helping to achieve a natural wood grain appearance. However, this type of first-generation or traditional composite decking boards do go through a natural weathering process. For the first 3-6 months of the decking boards life, they will fade from the suns UV rays. However, good quality boards will colour stabilize after this initial weathering period due to the manufacturing process that makes use of Grade “A” quality recycled plastics. These plastics are of the highest quality and are mainly imported from the USA and Europe to produce a composite decking board with improved fade resistance properties built-in. Although the colour fade during the first 3 months is gradual and very minor which most customers even rarely notice.

Traditional composite decking will last for at least 25 years and is normally backed with a 10-15 year warranty. It won’t splinter, warp, split, rot, twist in this 25-year cycle. The boards are safe to walk on barefooted and are child and pet-friendly. Traditional composite decking is anti-slip resistant and ideal for homes with hot tubs and children’s paddling pools.

Contrary to advice and information given by many decking manufacturers of no fading, all decking products, natural or engineered will experience weathering.

Next Generation Mixed Colours

First generation composite decking has continually evolved during its 30+ year life span. In the early 2000’s a printed wood grain finish was introduced and further evolving in 2010 onwards to a deep embossed wood grain finish that is surface treated, brushed and sanded to provide a cleaner and more authentic wood look.

The latest techniques and methods being used to perfect a natural wood grain appearance is with the use of computer-aided technology (CAD) borrowed from the aerospace and car industries to introduce a mix of colours at randomly programmed intervals to provide lighter and darker colours offering a further authentic wood appearance indistinguishable from real wood.

The latest techniques and methods being used to perfect a natural wood grain appearance is with the use of computer-aided technology (CAD) borrowed from the aerospace and car industries to introduce a mix of colours at randomly programmed intervals to provide lighter and darker colours offering a further authentic wood appearance indistinguishable from real wood.

Ultra-Decking are proud to announce the next generation of wood plastic composite decking created in this series for 2019. The new and exclusive natural collection range from Ultra Decking takes the beauty and authentic wood appearance to a whole new level.

Our mission statement at Ultra Decking is Ultra Quality with Ultra Style at an Ultra-Price point to continue to bring to our UK customers the very latest innovative designs in wood plastic composite technology.

These next-generation wood plastic composite decking boards come with two design profiles. A square hollow structure specifically designed and developed for our residential customers. Extensive market research and product development has produced the next generation of wood plastic composite decking boards that really need to be seen to believe they are not actually regular timber but with none of the maintenance drawbacks associated with wooden or timber decks.

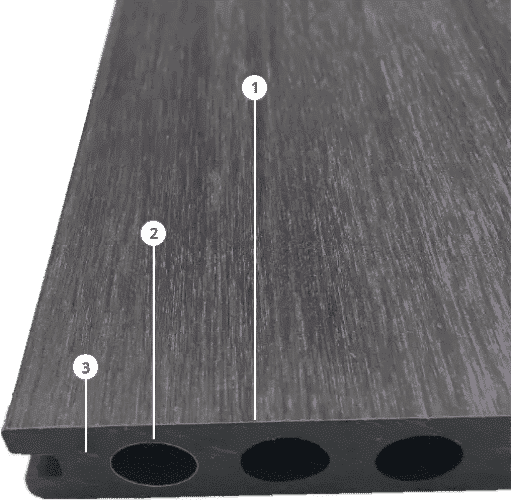

Analysis and studies confirm an average of 2.4 people resides at each UK household. The average weight of a person is 77kg with 231kg of weight placed on the decking at any given time. The key reason for this study and analysis was to ensure our new next generation of wood plastic composite decking boards when installed correctly has the structural strength and durability to last our customers between 15-20 years. Each decking board profile consists of a square hollow design and 6mm wall profiles with an overall depth of 21mm. The design conforms to SGS & Intertek standards that offers high-end structural strength together with Ultra Decking’s manufacturing quality to guarantee the life span of our exclusive next-generation composite decking products for 15 years.

Second Generation – Capped (Co-Extrusion) Decking

Second-Generation wood plastic composite decking is by the far the best decking solution the market has to offer. The shielded or capped core adds further durability and resistance to mother nature’s harshest elements such as mould, mildew and sunlight.

Second-generation was introduced into the USA market, as the promise of first-generation WPC decking being completely maintenance free, resistant to UV fading, staining, mould and mildew were was short lived.

Therefore, the industry was forced to adopt and embarked on sustained research and development to produce an Ultra-Low maintenance product that did truly resist fading, staining, mould and mildew. Hence the birth of second-generation wood plastic composite decking with a 0.5mm capped or shielded surface texture. This ensured that your new composite deck did indeed offer a low or no maintenance decking solution able to resist UV fade, staining, mould and mildew.

Customers reacted very positively to the introduction of second-generation composite decking and today you will find that in some global markets only second-generation composite decking is on offer with first generation composite decking being completely discontinued.

The only negative feedback of the new second-generation shielded technology was that the boards appeared to look plastic and cheap in their appearance and did not really provide the authentic wood look appearance research set out to achieve.

The cheap plastic appearance did put customers off from purchasing. The market was demanding an authentic wood look, colour retention without the annoying maintenance associated with wood. So far second generation composite decking board had failed to achieve a natural wood look, indeed even today some manufacturers are still failing to achieve an authentic wood appearance producing what looks like cheap plastic boards.

Ultra Decking listened and continued to perfect their designs and manufacturing processes to produce a composite decking board indistinguishable from real wood.

Lets Compare All The Different Generation Of Decking

Hopefully know you should have a better understanding of the composite boards in the market today. All have these advantages and disadvantages to help further on the pros and cons of all the different decking options we put together a overview of all the decking options available and bullet point the pro and the cons, first up is wood.

1 Wood Decking

Wood decking needs no introduction, it’s one of the most used decking solutions on the market, it comes in all different shapes and sizes, softwood to pressure treated, cedar, Ipe and redwood amongst others.

- Wood Look

- Can be cheap – often softwood

- Is Extremely Slippery

- Contribute to deforestation

- Lifespan can vary and be very short

- Will rot, warp and splinters

- Needs a lot of maintenance

- Can fade considerably in a short space of time

- Can be expensive – Cedar, IPE and redwood

- Can Crack

- Will become a hazard for children & pets

2 Uncapped Composite Boards

Uncapped composite boards are the first edition of composite decking produced, they have a wood fibre based surface which provides an authentic wood look and even through second generation was produced to improve the maintenance and colour consistency, uncapped boards stay popular today due to there competitive price and low maintenance. They many benefits consist of:

- Wood Look

- Anti-Slip

- Doesn’t need sealing or staining

- Doesn’t rot, warp or splinter

- Low maintenance

- 3% water absorption

- Lightweight

- Eco-Friendly

- Long lifespan

- Water resistant

- Hollow design

- Child & Pet Safe

- Lower fire risk compared with wood decking solutions

- Colour choices

- Frequent hosing required to prevent the build-up of mildew

3 Capped Boards

Capped composite boards was introduced into the market to eliminate some of issues in which first generation boards had. Uncapped first generation composite decking was marketed as low maintenance, no fading and no staining, but due to there wood fibre surface this was false and consumers become frustrated, enter capped decking with a PE surface layer that absorb minimal moisture and see minimal colour change year on, their many benefits are listed below:

- Wood Look

- Anti-Slip

- Fade Resistant

- Doesn’t rot, warp or splinter

- Doesn’t need sealing or staining

- Minimum 25-year lifespan

- Stops mould and mildew

- 1% water absorption

- Ultra-low maintenance

- Eco-Friendly and green

- Completely water resistant

- Child & pet friendly

- Colour choices

- Lower fire risk compared to wood decking

- Strengthened Honeycomb Core Design

- Extremely Durable

- Sounds too good to be true, order a sample and decide for yourself

Conclusion

There are two generations of composite decking, first-generation is manufactured from recycled wood fibres and HDPE plastics at its core. The wood fibres give the first generation a raw natural authentic wood look. As the surface of first-generation composite decking has a wood fibre surface the boards will go through a natural weathering process, in layman’s terms the colour will lighten slightly but by no means will the boards lose their colour. As the colour fade is very minimal, many customers don’t even notice the change.

There are many types of first-generation composite decking. Some come with thin or wide grooves, early designs had a printed-on wood grain surface. The latest first-generation composite decking boards come with a deep embossed wood grain appearance. Second generation or shielded composite decking boards have 2 different finishes which are either a very smooth surface texture similar in appearance to indoor flooring, a natural wood grain appearance or a grooved surface finish.

Second generation composite decking boards are produced with shielded or capped technology surface texture, the shield technology ensures all second-generation composite decking boards are able to retain their colour from original purchase and are also resistant to staining, fading, mould and mildew. Second Generation boards are more durable and longer lasting coming with an industry standard 25-year warranty.

Shield Technology