How To Clean Your Composite Deck

Composite Decking Installation Guide

Whether you are an experienced fitter or are choosing to complete your decking project yourself, we have created a simple step-by-step installation guide to laying your composite decking. Additionally, we have compiled some of the most frequently asked questions customers have when it comes to the installation of decking to ease the process even further.

Key Installation Point For Composite Decking

Before we begin its important to remember with composite decking installation: expansion, drainage, joist centres and airflow to quickly display, please see bullet points below for the key information to remember during installing your composite decking:

- Expansion – composite decking expands in the heat and contract in the cold and gaps must be left for this 3mm side to side and 6mm end to end

- Drainage – a gradient of 2.5% or 1/40 is key to leave to eliminate any future issue with water pooling or boards becoming damaged

- Airflow- good ventilation is key for a long lasting deck and a raised deck of 300mm is advisable

- Joist centre – your joist centre must be 300mm for domestic and 200mm for commercial or diagonal design

FAQs from customers

However, if you are unsure about any part of the installation process, we recommend hiring a professional to complete the job for you to ensure safety and accuracy. If you are constructing your decking project yourself, be sure to wear protective equipment for your safety.

The smaller the joist centres, the stronger the decking will be and will be able to withstand a higher footfall, which is why a smaller joist centre is required with commercial projects that will experience a much higher footfall than decking in a residential property. It is also recommended to have smaller joist centres if you are planning on putting heavy furniture or objects on the surface of your decking to avoid damage to the boards.

Additionally, your decking should be laid perpendicular to or at a 45-degree angle to the joists in the subframe to ensure structural integrity.

Posts can be anchored or dug into the ground and concreted in place or if your existing surface is already an even concrete surface, you do not need to raise the subframe. You can also use pedestals or composite battens.

Raised decking is required when the ground is uneven to create a flat and stable decking.

Planning permission is required if your decking exceeds 50% of the area of your garden or exceeds 30cm in height. Failure to adhere to planning regulations can result in fines and even legal action.

General Step-by-Step Installation Guide

Important Note: Before installing, you must allow your composite boards to climatise outside for at least 48 hours.

Video or Steps: you can choose to watch our video below on installing composite decking or if you prefer step by step written installation instruction, just simple scroll past.

Tools required:

- String/ Measuring Tape

- Spirt Level

- Shovel/ Skip

- Hammer/Screw Driver

- Circular Saw

- 60-80 Teeth Saw Blade

- Power Drill

- Rubber Malt

- Mitre Saw

- Dust Mask / Safety Glasses

Tools required:

- Gravel

- Weed Membrane

- Concrete Dry Mix

- Posts -100mm x 100mm

- Joists - C16 or Composite

- Joist Hangers

- Starter Clips

- Decking Clips or Screw

- Decking Boards

Step 1

Once all your tools and materials are ready and at hand, you will need to map out the space you will be installing. Use a tape measure to ensure you are measuring the correct dimensions and use pegs and string to mark the area you are going to be digging up.

Step 2

Using a shovel, dig up any grass or debris to create a clear, even surface for your subframe. Utilise a spirit level or laser level to ensure a flat surface.

Step 3

Lay your weed membrane down on your existing ground, cutting to allow for post-installation, remembering to remove 50/100mm of top of the soil as this will stop weeds from growing through your decking boards, which can damage your boards and create drainage issues. You can also opt to add gravel to your base to improved drainage further.

There are different quality of weed membrane and we would recommend using a non woven weed membrane as they have don’t pierce easily offering increased strength, durability and drainage. Please see from the image below for example.

Step 4

Once your membrane is laid, you will now need to dig the holes that your post will sit in. Dig 700mm deep holes, spaced 1.5m apart. It is imperative to create a slight gradient when installing your posts of 2.5% to allow for surface runoff away from your property. This must be considered when installing your posts, as this is how the gradient of your subframe is created.

Step 5

Most fitters build the frame before installing the post why? as this helps with measurements of the frame, must fitter will use the pre built frame to mark where there post will be placed, this ensures you consistency keep your frame and post level, as you can check as you go along. This can also support with pencil marking where noggins will be too.

Step 6

Which ever way you feel is best and fits your preferred fitting style can be done. When installing your posts, some great tips are sitting the post on bricks within the pre dug holes to lift the treated post from the ground, this help to minimal any moisture absorption over time.

Once you post are in the ground, create your concrete mix and pour it into the holes with the posts accurately vertical inside the hole to secure the posts in place, then allow them to dry, when appealing your postcrete, pack in with a wooden batten to ensure its compact around the post

Step 7

Once all the posts are securely in place, you can begin to construct your subframe. Your subframe is the most important part of the installation process, as it provides your decking with stability. Your subframe is constructed with joists that connect with joist hangers. Your joists can be either timber or composite, depending on your preference. We recommend composite or treated timber for longevity.

Step 8

Connect your joists, starting with the outside frame first cut and connect the length and width together, at this stage is key to remember the way your boards will be running ensuring the outside beam is measured and built in line with the frames dimensions.

Then working in a grid formation for the your landings (joist centres) and then noggins to build the rest of your frame. Simply drill your joist hangers into your outside frame, this will connect your landings (joists) together and correct structural galvanised screw or nails, and then the joists can connect easily.

Step 9

We would always recommend adding noggins with your subframe, noggin are over looked upon building a decking subframe but there play a crucial role in supporting the frame over the years providing increased strength and stiff to your subframe.

We would recommend for maximum stability and strength to add posts next to a noggin in which you can see in the image below.

Step 10

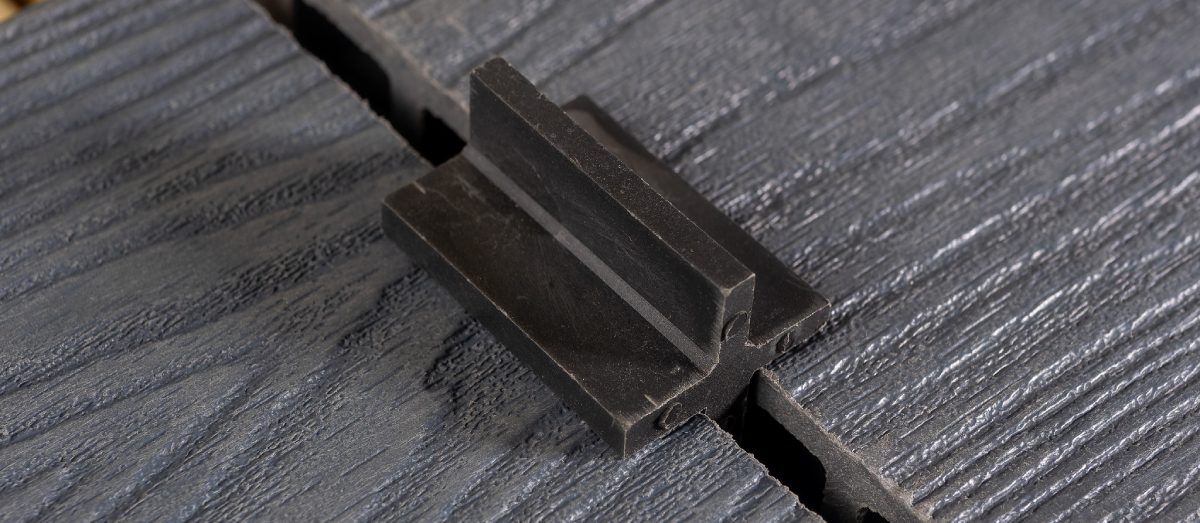

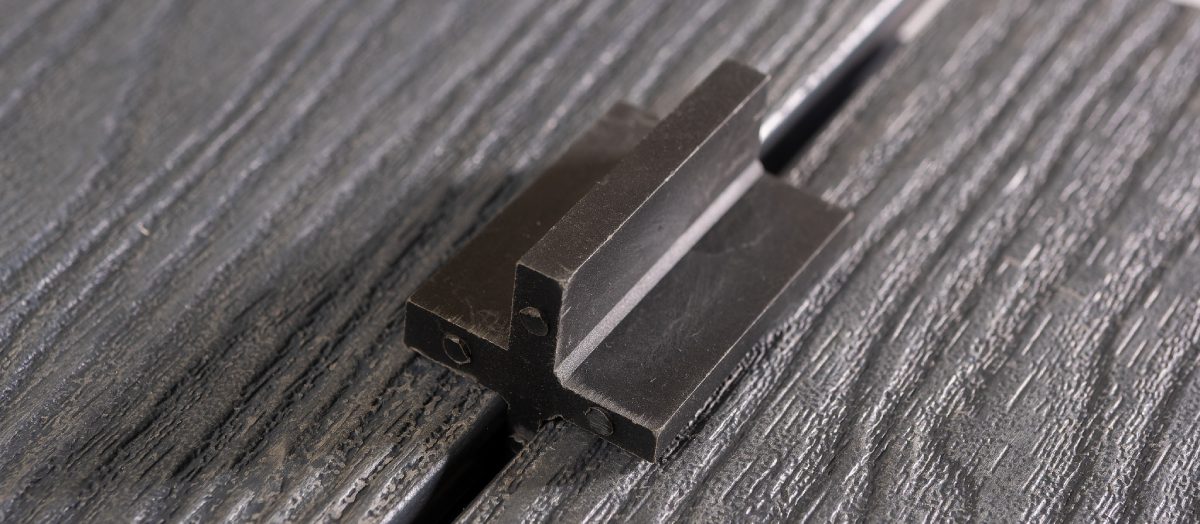

Once your subframe is accurately completed, you are ready to lay your decking boards utilising your starter clip and hidden fastener system. Before starting its key to remember that you composite decking boards need to be installed 20mm away from any fixed objects e.g. fence, wall or house.

Insert the first few boards by clipping the starter clips into the grooved channel at the side of your composite boards and connecting them. Transition over to our hidden fastener system after the first few boards to repeat the process.

Step 11

Composite Decking boards should be positioned in the direction of the gradient, this helps any water to naturally disperse. Screw your starter clips into position along with each joist spacing (300mm domestic & 200mm commercial) and slot your first deck board into the starter clips. Tap and fix into position with your rubber mallet.

Please remember, it is important to note that you must not screw or nail through the composite decking as this will cause cracking or raised screws over the years. If you are using bullnose boards these must be fitted first upon installation.

Make sure that the composite decking boards do not overhang the joists by more than 15mm.

Step 12

Next place a slim metal clip into the groove of the first board. Screw it into place, do not force or push hard into place and ensure a 3mm gap is left side to side. You should use one clip on every joist. Take the second piece of the deck and place it into the clips.

Please note when using slim metal clips on our home choice collection that the screw goes into the counter sunk central whole, one screw is used on each clip.

Step 13

Now place a clip into the groove of the second board and screw to secure it against the first board, but do not over-tighten or force. Now continue this process using one clip on one screw on every joist.

Step 14

When boards meet end to end, you must allow for expansion space. Depending on the temperature, you should leave a gap of between 6mm and 8mm (note below 10 degree a 8-10mm gap must be left).

Step 15

You should also make sure that any decking boards joining end to end has a double joist underneath and use a clip to secure each end of the decking boards.

Step 16

As mentioned above its key to note that 3mm side to side must be left, even if your using the slim clip or 3mm clip this must be checked as you are installing and don’t automatically believe that this will be done. Composite boards expand in all directions and depending how stored or left, curving of the board can occur.

Step 17

When using plastic clips the process upon fitting is very similar. Place a plastic clip into the groove of the first composite decking board and screw it into place but do not screw all the way. You should use one clip on every joist. Now place a clip into the groove of the second board and screw to secure it against the first board, but do not over-tighten or force. Now continue this process using one clip on one screw on every joist. When fitting the last board with a plastic clip, first measure the width of the final two boards to find where the outer edge of the final board will lie. Using these marks, fit starter clips and slot the last board into place. Now insert the penultimate board and slide down the required number of clips. Screw these clips into place

Step 18

To fit the final board (only when slim metal clips are being used). With the last board in place after securing all other boards, screw through the groove of the last board at an 45 degree angle, securing it to the joist at 300mm intervals, Pre-drill pilot holes in the deck boards 2-4mm wider than the width as the screw shank. Do not over drive screws into the deck boards to avoid the material splitting.

Once all yours boards are fitted, any overhanging you can use a plunge saw to cut the length perfectly in position with one single cut.

Don’t forget you may have to cut around any fix objects, man holes, drain pipes or posts with a jigsaw to provide a neat finish (remembering and expansion gaps).

Step 19

If a board is bowed or curved, please install at each end first and moving up the length of the board in turn will push the board back into position. It is recommend to check this as you install your composite decking boards. If you leave bowing with your decking boards, over the coming years this can create boards to pull out of position as they expand.

Don’t forget to mix and match the boards to allow for a blend of colours and a mix of patterns on wood grain finished boards. You should also stagger the boards to create a brick work effect if you so wish.

Remember, composite decking is scratch resistant not scratch proof. Ultra Decking recommended that furniture placed on any composite deck is fitted with rubber or felt feet to prevent unnecessary scrapes.

Step 20

Bullnose boards allow you to create a flush finish without adding a fascia or an angled corner trim. To fit a bullnose board simply add starter clips into the designated location on the bottom of the board. Then slide the bullnose board into place and push forward to secure in to place with the clip ready for the next board to be laid. You can adjust the spacing of your starter clips to achieve an overhang or flush finish. To fit Ultra Decking onto steps, bullnose boards can be used. Add the decking starting from the bottom step, then place your bullnose boards into place.

Step 21

When installing fascia & angled corner trims please ensure you leave a gap to allow for expansion at the ends.

When installing angle trims, these can be glued in to place using a commercial grade adhesive or secured in to place with suitable screws drilling pilot holes 2-4mm wider than the screw shank at 300mm intervals screwing into the timber or composite joists at a 90 degree angle.

Step 22

Once all the above steps have been completed accurately, you have successfully finished installing your decking.