Starting You Build Of Joists

Choose the Right Joist :

In our experience, the best option for choice of joist considering price and durability is a C24 pressure treated joist.

These joists provide long-term strength and performance.

We firmly recommend using the enhanced C24 graded pressure-treated wood for your joists.

Build Your Outer Frame:

Most fitters find it easier and more accurate to build the main outer box frame first.

Cut your C24 joists to size and fix them together with galvanised structural screws. You can even place the outer frame on the ground to check dimensions and mark your post positions accurately before digging.

Install the Inner Joists:

Attach galvanised joist hangers to the inside of your outer frame. Then, slot your inner joists into the hangers and secure them.

Add Noggins:

Fit shorter pieces of joist (noggins) in a staggered pattern between your main joists. This is a crucial step that many DIYers miss. It prevents the joists from twisting over time and adds huge rigidity to the entire frame.

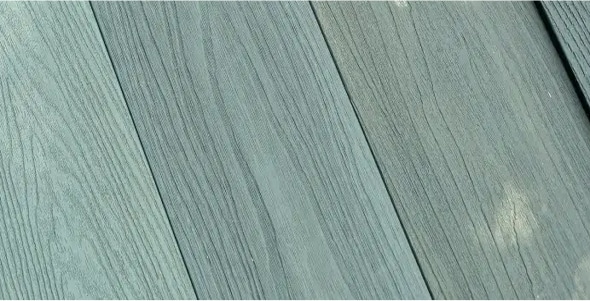

Joist Spacing:

For residential decks, the space between the centre of one joist and the centre of the next must not exceed 300mm. For commercial projects or diagonal board layouts, reduce this to 250mm.

Previous Article

Previous Article