Wood Vs Composite Decking

Some Solid Decking Board companies are publishing a lot of negative information regarding Hollow Decking Boards. Yes, they do use less material and are normally cheaper. However, Hollow Decking Boards are designed and engineered for their strength and durability.

A good reason for this negative publicity, is solid boards are more expensive when compared to a hollow. They use more materials and due to there increase in weight they are more expensive to transport further increasing the costs to purchase a solid board.

You may also find surprising is that solid composites boards in most cases tend to be easier and faster to produce when compared with a hollow. Many manufacturers don’t have the skills, knowledge or latest machine technology to extrude a Hollow Decking Board.

How Strong Is Hollow Decking?

Ultra-Decking’s Signature WPC composite boards are manufactured with a circular honeycomb core, mimicking Mother Nature’s toughest structures. Indeed, many species of insects such as bees and ants use a honeycomb structure in their hives and nests. Tests have shown that a honeycomb structure offer exceptional strength to weight ratio.

Unlike some solid decking boards, a hollow decking board are less susceptible to warp, twist or bend. Ultra-Decking boards are made using manufacturing process to produce a circular core, achieving stiffness and exceptional strength to weight ratio not found in solid composite boards. A circular honeycomb core offers an even weight distribution versus a rectangular or square core which has weak points at the centre and at each corner. For example, A metal circular tube can take more weight than a square one.

All Ultra Decking range’s of composite decking boards have been independently inspected and tested by SGS, a leading global test and inspection organisation confirming the boards quality, strength and durability in the harshest of conditions.

Weather And Temperature Fluctuations

A composite decking board manufactured with a Hollow or Honeycomb Core is less impervious to the weather. Sudden changes in temperature and moisture fluctuations can cause solid decking boards to expand or contract over time.

These sudden temperature changes can loosen fixtures and fittings causing movement which can lead to warping or raised screws.

The core of a hollow composite decking board can easily expand and contract, therefore are less impervious to rapid changes in weather and temperature which are typically associated with UK weather conditions.

Square Hollow

Square hollow decking boards are one of the most commonly sold composite boards in the U.K. They are mainly sold in an uncapped first generation surface finish, with a grooved or wood grain pattern.

Extra checks must be taken into account when purchasing a square hollow structure. Out of all the boards profiles designs a square is the weakest but offers the best price when compared to any other composite boards, making it very appealing for all users. This is due to less materials being used during production.

As mentioned the square hollow core is a commonly sold in an design in here in the UK. Most customers’ first thoughts are that the deeper or thicker the decking board is the stronger it will be. This isn’t always true. When choosing a square hollow composite decking board, the most important part to confirm and check is the depth of the top and side walls inside the square core. Regardless of the board’s overall depth, the square core top and walls should be at least a minimum of 5mm on each side wall, including the top and bottom of the square core. If the walls and tops of the square core fall below 5 mm, the strength is more than likely very weak. This might lead to structural problems such as cracking, splitting or even failure over time.

Another great key point to pay close attention to when purchasing a square hollow is the amount of hollows in the core, the main square hollows designs in the UK are 4 and 5 square hollows, 4 square hollow is weaker than 5, due to the amount of pillars used in the core, similar to a building structure the more pillars, the more strength and weight baring, so the more square in the core the more strength.

In summary, a square hollow core decking board of any thickness for residential/home decking projects must be a minimum of 5 mm in depth on the side and top walls to ensure the required strength over the deck’s service life.

Next is the joist spacing, if you are using a square hollow then your joist centre in our experience should not exceed 300mm. Going over these guidelines could create structure fail, warping or sagging in the later years.

As long as the boards are purchased with the correct due-diligence in relation to the square thickness and inner thickness , along with the correct installation then these boards are most certainly a brilliant investment for home owners

Ultra Decking’s home choice range of composite decking boards are 150mm wide and 25mm deep, with a inner thickness of 5mm.

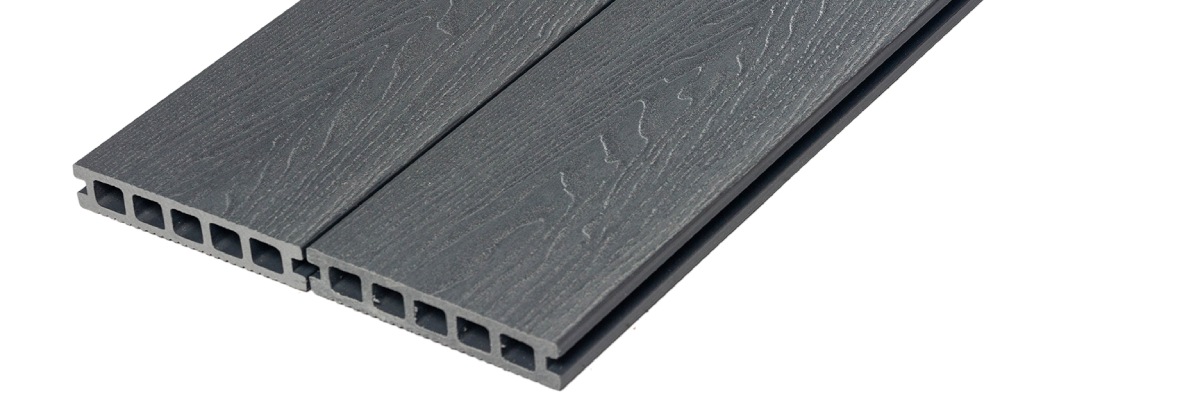

Circular Hollow

A circle hollow is the best mix of a solid and a hollow in our personally view, the circle hollow offers similar strength of a solid without the drawbacks of increased expansions rates.

These hollow design boards are perfect for long performing boards with home owners that want the extra piece of mind and for commercial project that require the extra strength and durability.

Independent tests from SGS have confirmed that Ultra Decking’s signature range of composite boards can withstand the stress and weight of up to 4 average family cars before failure. The signature range of composite boards is recommended for areas with public access and high footfall. Of course, residential customers can opt for the added strength and durability for that lasting peace of mind.

For commercial customers, we strongly recommend a circular hollow core as the smart choice. Ultra Decking’s Signature ranges are designed and built to withstand high footfall areas, offering many years of service. Circular hollow cores can distribute impact or shock waves evenly throughout their core and easily deal with the harshest weather conditions, especially changes to temperature fluctuations experienced here in the UK.

Many industry experts and analysts recommend a circular hollow core because it improves strength features and is better equipped to deal with temperature contraction and expansion.

These boards are more cost effective than purchasing compared to a solid profile and can last just as long if longer, This is why ultra decking offer this profile design in their signature collection, as we feel this is the very best option for any user.

Please bare in mind that joist centre will need to be 300mm to ensure the durability and longevity of the performance.

In summary, a circular hollow core board is the best choice for commercial usage. It offers similar strength to a solid board and gives it flexibility for expansion and contraction.

Solid Profile

A solid profile is most defiantly the most durable in strength overall. Producing on average over 40mpa based on 300mm joist centres. This strength enables customers to span up to 400mm to 450mm on joist centre reducing labour and materials costs.

The only drawback in a solid profile is the price, even with the reduction in materials, the up front cost will mean extra spend overall, in our view we would only recommend a solid profile in heavy commercial usage in which could return the investment over the years. Subject to quality, they have no match in strength and are built to withstand large footfall or public areas and offer a long lifespan due to the boards dense design. Truth be told 9/10 projects a solid profile is not required in light commercial and most definitely in domestic settings.

The only downside to a solid composite decking board is expansion and contraction. The dense design does not easily stand up to fast temperature changes as easily as a hollow design. This can lead to movement causing warping in some instances.

Does Composite Decking Fade?