Filters

Showing all 15 results

Quality Composite Decking By Ultra Decking®

UK’s Decking Boards Specialist

Ultra Decking boards are hi-tech composite decking products that provide an eco-friendly alternative to wood decking. Our range of products has been created for all types of budgets and outdoor spaces. Hence, we are sure that, like our many happy customers, you will find the right composite decking board you need to transform your outdoor space!

Each of our collections has been designed and developed to focus on a variety of different outdoor projects and ideas. So, whether you are building a classic garden decking, pool area, luxurious outdoor garden floor, etc., rest assured that our product range will meet your needs.

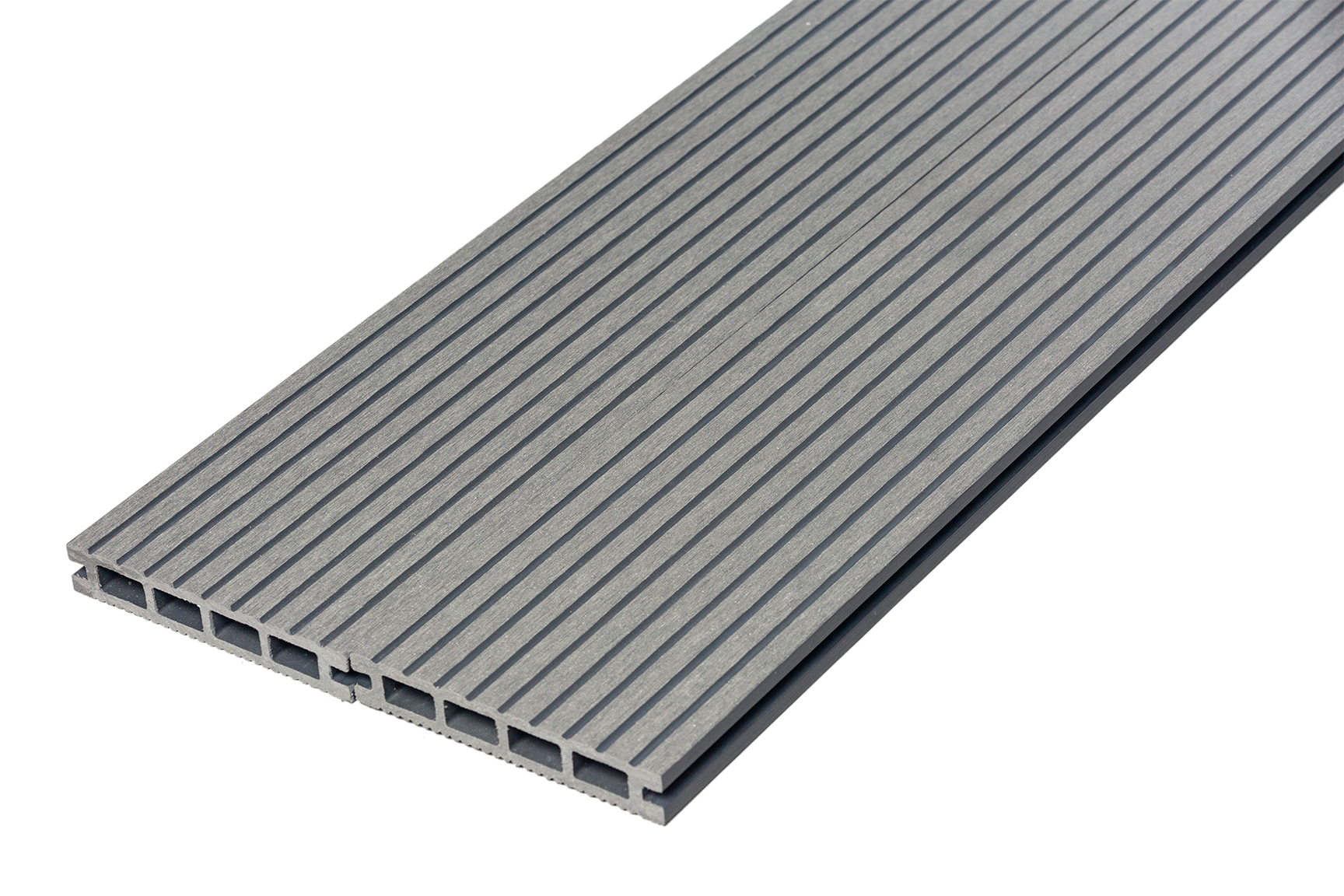

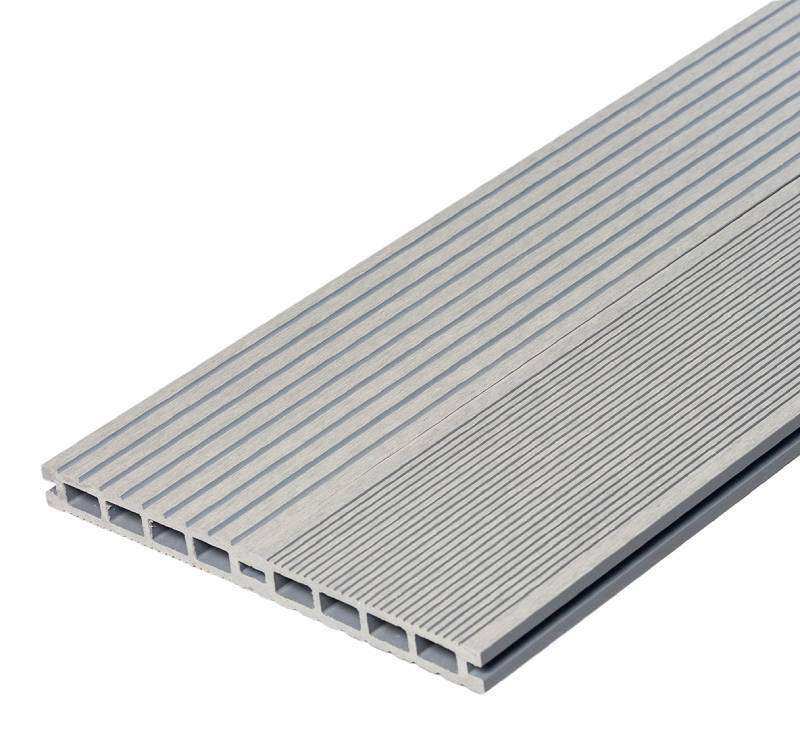

Home Choice Composite Decking

Transform your garden project into a beautiful outdoor living space with the perfect balance of quality, affordability and style.

Our Home Choice collection was designed & engineered with homeowners in mind. In other words, the goal was to create the perfect mix of affordability and durability. We do not compromise on the features, advantages and benefits of composite decking. As a result, our home choice collection has recently been awarded by expert reviews as the most cost-effective decking product on the market today.

Our Home Choice Premier is highly rated by homeowners and landscapers. For instance, it has an excellent anti-slip & scratch-resistant properties. Independent landscape professionals rated our it as the best for scratch resistance in the composite decking sector.

Exclusive Natural Composite Decking Boards

The Exclusive Natural collection is an innovative first-generation with high-quality grade A recycled plastics and hardwood fibres.

This is manufactured using the latest composite production technology and techniques that capture the aesthetics and beauty of real exotic timber. In addition to none of the annual maintenance and drawbacks of timber or hardwood decking.

Also, professional landscapers has rated this Exclusive Natural collection as one of the most authentic composite decking board currently available.

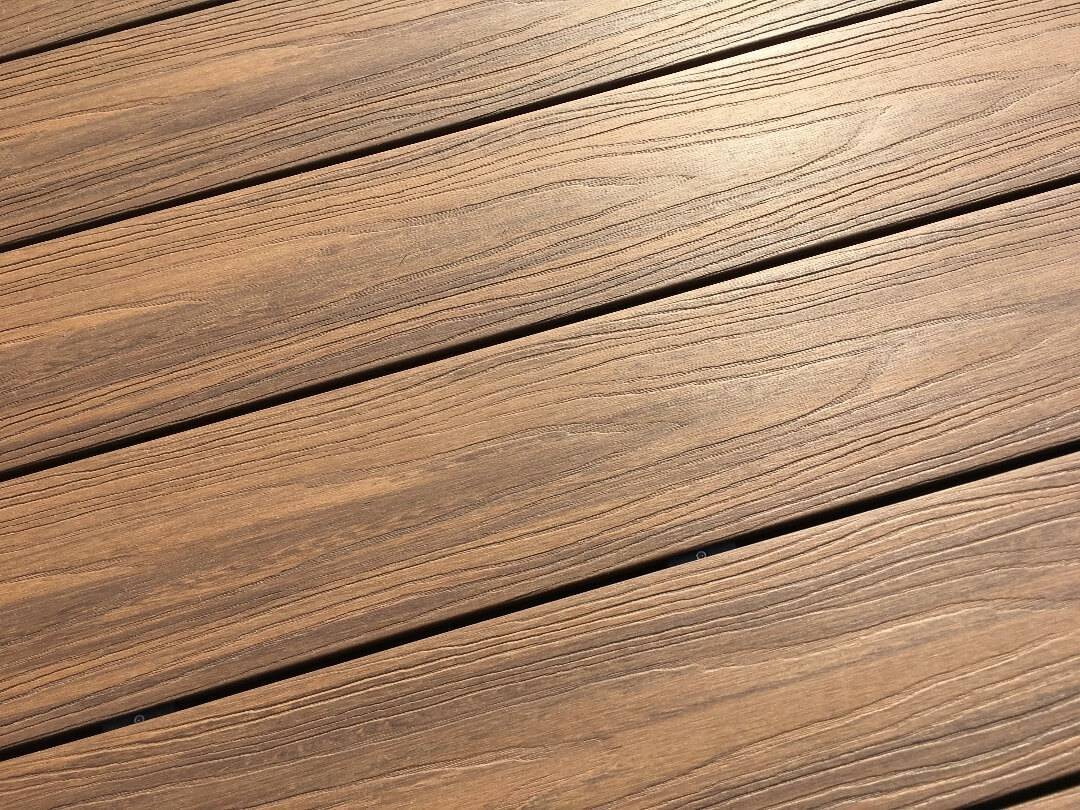

Signature Composite Decking Collection

Our Signature Collection is manufactured with a durable thin plastic layer that wraps around the entire board. As a result, not only will it enhance your outdoor space, but it also provides long-term colour stability and ultra-low maintenance. Most importantly, the added protection from spills and stains allows you to relax more during the hot summer months.

What do professional fitters say about it? Well, it been rated as one of the hassle-free decking solutions out there. In addition, it offers the perfect mix of beautiful aesthetics and durability with fade, stain and scratch-resistant properties and it comes with a 25-year limited guarantee.

Review Composite Decking Boards For Your Project

Product Performance Review |

Home CHOICE Collection |

Home PREMIER Collection |

Exclusive Natural Collection |

Signature Dual Colour Collection |

|---|---|---|---|---|

| Size | 3.6m | 2.4m/3.6m/4m/4.8m | 3.6m | 3.6m/4.8m |

| Surface Finish | Grooved | Wood Grain | Mixed Colour | Dual Colour |

| Core Design | 4 Square Hollow Composite Decking | 5 Square Hollow Composite Decking | 4 Hollow Grade A Plastic Composite Decking |

6 Hollow Capped Dual Coloured Composite Decking

✓✓✓✓ |

| Life Span* | 10 Year Residential* | 15 Years Residential* | Over 15 Years Residential* | Over 20 Years Residential* |

| Slip Resistance (Wet Conditions) |

Low Risk (Horizontal Installation)

✓✓✓✓ |

Low/Medium Risk (Horizontal Installation)

✓✓✓✓ |

Low Risk (Install Horizontally)

✓✓✓✓ |

Low/Medium Risk (Install Horizontally)

✓✓✓✓✓ |

| Weather Resistance |

Moderate

✓✓✓ |

High

✓✓✓✓ |

High From Using Grade A Plastics

✓✓✓✓ |

High (Capped Layer)

✓✓✓✓✓ |

| Affordability |

From £4.52 Per Metre

✓✓✓✓✓ |

From £5.09 Per Metre

✓✓✓✓✓ |

From £5.67 Per Metre

✓✓✓✓ |

From £6.25 Per Metre

✓✓✓ |

| Low Maintenance |

Wash Every Quarter*

✓✓✓ |

Wash Every Quarter*

✓✓✓✓ |

Wash Every Quarter*

✓✓✓✓ |

Wash Every 6 months*

✓✓✓✓✓ |

| Stain Resistance |

Low (Wood Powder Surface)

✓✓ |

Moderate (Improved Surface Finish)

✓✓✓ |

Moderate (Grade A Plastics)

✓✓✓ |

High (Capped Layer)

✓✓✓✓✓ |

| Scratch Resistance |

Moderate (Sanded Finish, Easily Repaired)

✓✓✓ |

High (Stronger Surface Finish)

✓✓✓✓ |

Moderate

✓✓✓ |

Low (Thin Plastic Layer)

✓✓ |

| Fade Resistance |

Low (Depending On Colour)

✓✓✓ |

High (Improved For 2023)

✓✓✓✓ |

Mid Resistance

✓✓✓ |

High (Minimal Colour Reduction)

✓✓✓✓✓ |

| Installation |

Clips With 300mm Joist Centre

✓✓✓✓✓ |

Clips With 300mm Joist Centre

✓✓✓✓✓ |

Clips With Joist Centre 300mm

✓✓✓✓✓ |

Clips With Joist Centre 300mm

✓✓✓✓✓ |

Tips for Composite Decking Installation

Installing composite decking boards in your garden is simple and quick. First of all, it’s important to remember to purchase all the approved decking accessories and materials required to complete your new project. For all decking accessories, please visit our accessories page.

When installing your new decking, there are some key points to remember.

- Expansion – All composite decking will expand due to either thermal expansion or moisture absorption. It’s important you leave a 3mm gap side to side and a 6mm gap end to end.

- Joist Spacing – Joist centres should be spaced at 300mm for residential and 200mm for commercial use.

- Airflow & Drainage – the decking area should not hold water and must drain water easily. Increase the gradient and test during and after installation.

- Still unsure watch our video below.

Ultradecking Trusted Reviews

FAQ’s

Common questions our customers ask us about our products range

Composite decking boards by Ultra Decking are usually priced between £19.99 – £26.99 per 3.6m board. For an accurate quote for your square meterage, please give us a call on 01925 943011.

You can expect the longevity and durability of last up to 25 years. Having said this, there are a few key factors which should be taken into consideration if you would like your decking to last this long.

In the summer months when your decking is exposed to sunlight, you may find that it becomes warmer – however this won’t leave you running for the closest shaded area!

Like most surfaces, it can become slippery, especially when wet. Having said that; good-quality composite decking boards, that are produced to high standards, are developed with built-in anti-slip properties which make them less slippery.

At Ultra Decking we recommend spot cleaning as and when your decking requires this, however we would suggest a deep clean every few months to ensure your decking is kept clean.